Thermal imaging cameras have transformed the way professionals assess and troubleshoot building structures in the field of building diagnostics. These advanced tools make it easier to detect moisture issues, which are often hidden from the naked eye. By capturing infrared radiation, thermal imaging cameras provide critical insights into energy efficiency, structural integrity, and potential moisture problems. Whether you're a building inspector, energy auditor, or facility manager, these devices can streamline your diagnostic process. In this blog, we'll explore the key applications and benefits of thermal imaging cameras in building diagnostics.

What is Thermal Imaging?

Thermal imagers work by detecting the infrared radiation emitted by objects and converting it into a visible image. Unlike traditional digital cameras that rely on visible light, thermal imaging cameras use heat signatures to create images. This technology has revolutionized many industries around the world, making invisible details visible. Initially used for military and security purposes, thermal imaging has now expanded into various fields such as construction, energy auditing, and building maintenance. With thermal imaging, we can now see what our eyes cannot—helping us identify issues before they become major problems.

Key Applications of Thermal Imaging Cameras in Building Diagnostics

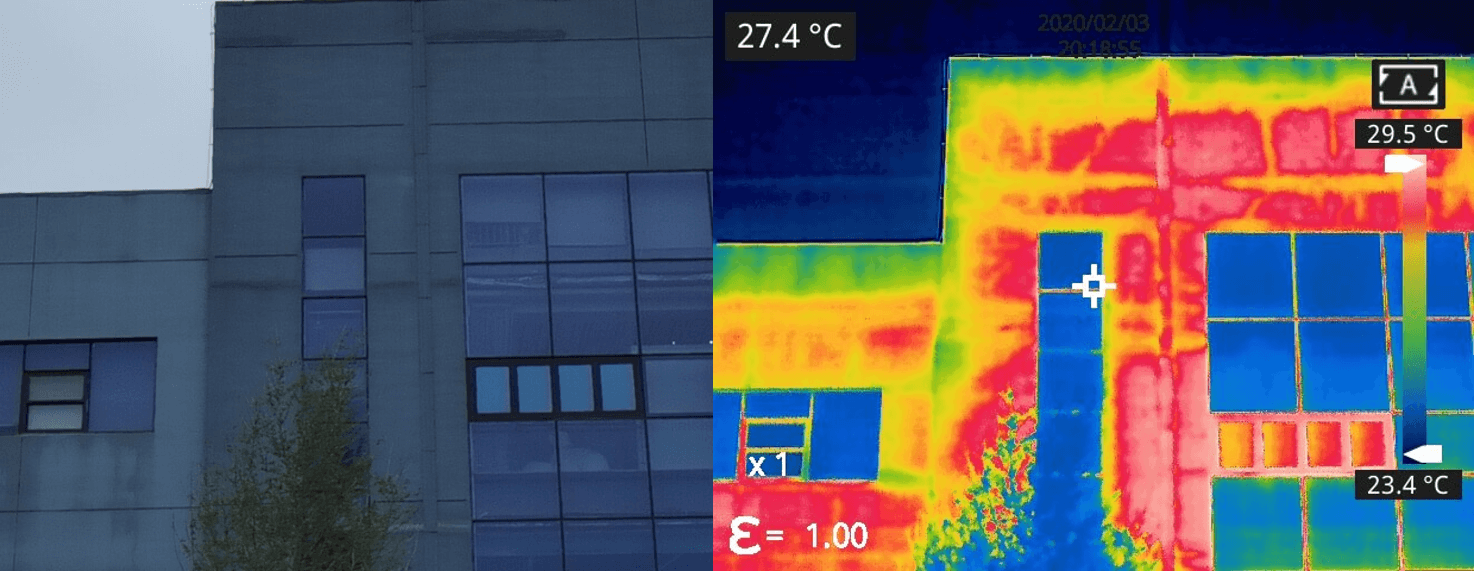

- Assessing Energy Efficiency: One of the most common uses of thermal imaging in buildings is conducting energy audits. By scanning doors, windows, and walls, thermal cameras can detect air leaks, insulation gaps, and heat loss in HVAC systems. This helps improve energy performance and reduce utility costs.

- Detecting Moisture Issues: Moisture problems in buildings can lead to mold growth and structural damage if left unchecked. Thermal imaging cameras are highly effective at identifying moisture sources, as wet areas tend to be cooler than dry ones. This allows for quick and accurate detection of leaks, especially around plumbing systems and foundations, preventing costly repairs down the line.

- Roof Inspections: Identifying roof issues without invasive methods can be difficult. Thermal imaging offers a non-intrusive solution by revealing heat leaks, moisture buildup, and structural weaknesses. This helps in early detection of potential roof failures.

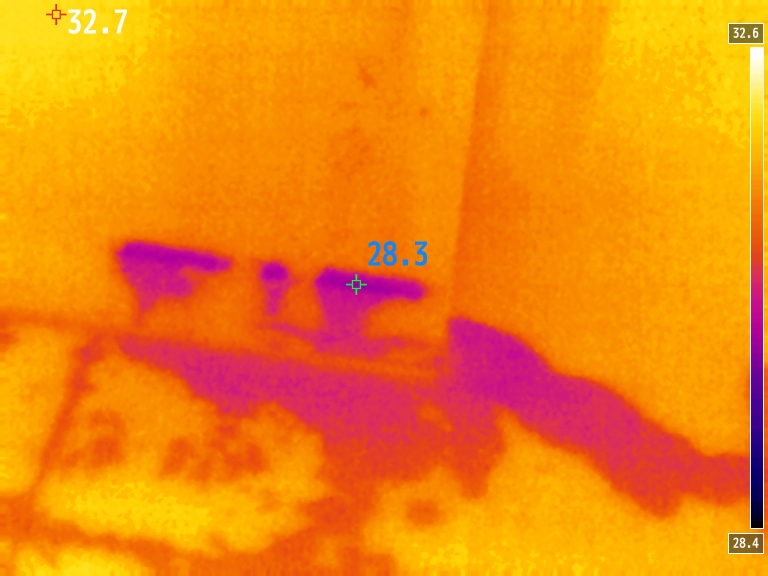

- Electrical System Checks: Many electrical components operate continuously in buildings, and faulty connections or overloaded circuits can lead to fires. Thermal imaging cameras quickly spot hotspots that indicate potential electrical failures, allowing for timely maintenance and preventing dangerous situations.

Benefits of Using Thermal Imaging Cameras in Building Diagnostics

- Fast and Efficient: Thermal imaging cameras allow for rapid assessments of large areas with a single scan. Unlike traditional temperature measurement tools that require component-by-component checks, thermal imaging provides an immediate overview of the entire structure.

- Cost-Effective: Regular thermal inspections help identify small issues before they escalate into expensive repairs. By catching problems early, you can save money on future maintenance and avoid more extensive damage.

- Non-Invasive: Traditional inspection methods may require drilling holes or damaging walls, but thermal imaging allows for accurate diagnosis without any physical disruption. This preserves the integrity of the building while still providing detailed insights.

In conclusion, using thermal imaging cameras in building diagnostics is a smart and effective approach to maintaining the safety, efficiency, and longevity of structures. From energy audits and moisture detection to electrical inspections, thermal imaging offers a reliable, non-invasive, and fast solution. Its ability to reveal hidden thermal patterns makes it an invaluable tool across multiple industries. Integrating thermal imaging into routine building inspections can significantly enhance maintenance practices and overall safety for professionals in construction, facility management, and real estate.

Tempsens Instruments offers a range of high-quality thermal solutions tailored for various applications. Our Thermeye640 model, with a resolution of 640x480, is ideal for building diagnostics where precision is essential. The right camera can capture even the smallest details, ensuring accurate and reliable results. If you need assistance choosing the best thermal imaging solution for your needs, our experts are here to help. Contact us today and let us support your next project.

Read more at : catalog/non-contact-temperature-sensors/thermal-imagers/portable-thermal-imaging-camera.html

Galvanized Steel Pipe,Galvanized Hollow Steel Pipe,Hot Dipped Galvanized Steel Pipe,Dx51D Z Galvanized Steel Pipe

Shandong Yuzhong Steel Co.,Ltd. , https://www.cnyzsteel.com