Are you curious about the complex process of OEM sheet metal fabrication and the vital role OEMs play in the manufacturing sector? You’ve come to the right place! This comprehensive guide offers deep insights into the precision, technologies, quality control, customization, and collaborative partnerships inherent in the world of OEM sheet metal fabrication.

What You’ll Discover About OEM Sheet Metal Fabrication

This guide covers everything from the OEM sheet metal fabrication process and the technologies involved to quality control, customization, the role in the supply chain, partnerships, trends, case studies, sustainability, and how to choose the perfect OEM partner. We’ll also conclude with a spotlight on Atlas Manufacturing.

– The OEM sheet metal fabrication process, technologies, and quality control

– Specialization, supply chain contributions, partnerships, trends, and sustainability

– How to select the right OEM partner and our conclusion featuring Atlas Manufacturing

The OEM Sheet Metal Fabrication Process

OEM sheet metal fabrication involves meticulous steps to ensure precision and quality. From initial design and material selection to cutting, forming, and finishing, every phase requires careful attention to detail. Precision is non-negotiable in OEM processes to meet exact specifications and ensure seamless integration into the final product.

Why Precision and Quality Matter in OEM Processes

Precision and quality are essential in OEM sheet metal fabrication. The capability to adhere to tight tolerances and produce components with exceptional accuracy is a hallmark of top-tier OEM manufacturers. This unwavering commitment to precision ensures that fabricated parts fit perfectly into the larger manufacturing process, enhancing overall efficiency and functionality of the end product.

Technologies and Techniques in OEM Sheet Metal Fabrication

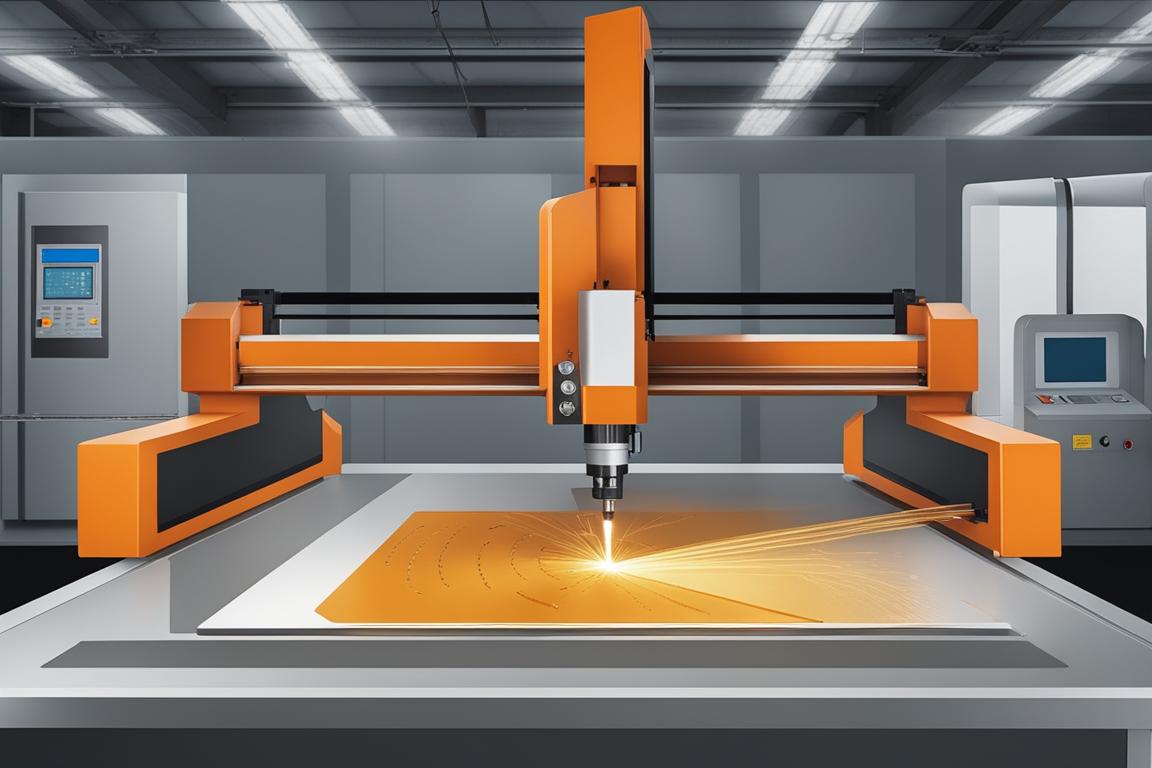

The field of OEM sheet metal fabrication is constantly evolving, integrating cutting-edge technologies and advanced techniques. OEMs utilize state-of-the-art machinery and processes to deliver superior quality and precision in their fabricated components.

An Overview of Advanced Machinery

OEMs employ a variety of advanced technologies such as punch presses for precise cutting, laser cutting for intricate designs, welding for joining metal components, machining for refining part dimensions, and forming for shaping metal sheets. These sophisticated techniques allow OEMs to meet the complex demands of modern sheet metal fabrication with efficiency and accuracy.

| Technology/Technique | Description |

|---|---|

| Punch Presses | Used for precise cutting of sheet metal with various tooling options. |

| Laser Cutting | Enables intricate designs and precise cutting of different metals. |

| Welding | Necessary for joining metal components together. |

| Machining | Applied for refining part dimensions and achieving high accuracy. |

| Forming | Involves shaping metal sheets into desired forms. |

Quality Control and Certification in OEM Sheet Metal Fabrication

Quality control is the backbone of OEM sheet metal fabrication, with certifications like ISO 9001:2015 highlighting the dedication of OEM manufacturers to uphold stringent quality standards.

The Importance of Maintaining High Standards

Certifications such as ISO 9001:2015 confirm an OEM’s commitment to maintaining robust quality management systems. Additionally, an unwavering focus on timely delivery, quality, and scalability ensures that OEMs consistently meet client needs while adhering to the highest standards of craftsmanship.

Customization and Specialization in OEM Sheet Metal Fabrication

OEM manufacturers offer tailored solutions and cater to the unique requirements of diverse industries.

Specialization in Producing Custom Parts

By specializing in creating custom parts designed for specific industries such as agriculture, construction, and material handling, OEMs showcase their versatility and adaptability. This specialization allows OEMs to address the specific challenges and demands of each industry, delivering solutions that align with the unique operational needs of their clients.

The Role of OEMs in the Manufacturing Supply Chain

OEM sheet metal fabricators play a crucial role in the broader manufacturing supply chain, contributing to the smooth production of various end products.

How OEMs Contribute to Different Industries

OEMs supply essential components that form the foundation of diverse products across industries. Their contributions to the manufacturing supply chain ensure the availability of high-quality, precision-engineered parts that drive innovation and efficiency in the production of finished goods.

Collaborative Partnerships in OEM Sheet Metal Fabrication

Collaborative partnerships between OEMs and manufacturers are key to fostering successful projects and achieving mutual growth and success.

The Benefits of Strong Partnerships

Building strong and lasting partnerships with OEMs encourages collaboration, innovation, and shared success. These partnerships enable manufacturers to tap into the expertise of OEMs, resulting in the development of high-quality products that meet and exceed industry standards.

Trends and Innovations in OEM Sheet Metal Fabrication

The OEM sheet metal fabrication industry is continuously evolving, driven by innovative trends and technological advancements that transform the manufacturing landscape.

Embracing New Technologies and Processes

OEMs are at the forefront of adopting new technologies and processes to improve the efficiency and quality of sheet metal fabrication. By staying current with the latest trends and innovations, OEMs continue to enhance their capabilities and deliver cutting-edge solutions to their clients.

Case Studies and Success Stories

Real-world examples of successful OEM sheet metal fabrication projects serve as proof of the expertise and impact of OEM manufacturers in the industry.

Highlighting Real-World Examples

Case studies and success stories demonstrate the exceptional outcomes achieved through collaboration with OEMs, showcasing their ability to deliver outstanding solutions that meet and exceed client expectations.

The Future of OEM Sheet Metal Fabrication and Sustainability

The future of OEM sheet metal fabrication is focused on sustainable practices and advancements that prioritize environmental responsibility.

Adopting Eco-Friendly Practices

OEMs are increasingly embracing environmentally friendly materials and sustainable processes to align with global efforts towards environmental conservation. This shift toward sustainability reflects the commitment of OEMs to responsible manufacturing practices.

Selecting the Right OEM Partner for Sheet Metal Fabrication

Choosing the ideal OEM partner is a critical decision for businesses seeking reliable and high-quality sheet metal fabrication services.

Key Factors for Selecting the Perfect OEM Partner

When selecting an OEM partner, businesses should consider factors such as the OEM’s capabilities, industry experience, and adherence to strict quality standards. Identifying a partner with a steadfast commitment to quality, innovation, and customer satisfaction is essential for successful collaborations.

Conclusion

OEMs are indispensable to the sheet metal fabrication industry, playing a pivotal role in delivering precision-engineered components that drive innovation and efficiency across diverse sectors. As the industry evolves, OEMs remain at the forefront of technological advancements and collaborative partnerships, ensuring the seamless integration of their fabricated parts into the broader manufacturing ecosystem.

Q & A

What exactly is OEM sheet metal fabrication?

OEM sheet metal fabrication involves producing custom metal parts specifically for original equipment manufacturers.

Who benefits from precision sheet metal fabrication?

Industries like automotive, aerospace, electronics, and telecommunications benefit greatly from precision sheet metal fabrication.

How does precision sheet metal fabrication differ from regular fabrication?

Precision sheet metal fabrication focuses on tight tolerances and high accuracy to meet specific OEM requirements.

Why is OEM sheet metal fabrication cost-effective?

Outsourcing to a specialized OEM sheet metal fabrication company allows businesses to take advantage of economies of scale and expertise.

How can I ensure the quality of my OEM sheet metal parts?

Look for a fabricator with ISO certifications, a proven track record, and robust quality control processes in place.

What if I need custom designs for my OEM sheet metal parts?

A reputable OEM sheet metal fabrication company can work with you to develop custom designs that meet your specific needs.

{"@context":"https://schema.org","@type":"FAQPage","mainEntity":[{"@type": "Question", "name": "What is OEM sheet metal fabrication?", "acceptedAnswer": {"@type": "Answer", "text": "OEM sheet metal fabrication involves producing custom metal parts for original equipment manufacturers."}}, {"@type": "Question", "name": "Who can benefit from precision sheet metal fabrication?", "acceptedAnswer": {"@type": "Answer", "text": "Industries such as automotive, aerospace, electronics, and telecommunications can benefit from precision sheet metal fabrication."}}, {"@type": "Question", "name": "How is precision sheet metal fabrication different from regular fabrication?", "acceptedAnswer": {"@type": "Answer", "text": "Precision sheet metal fabrication involves tight tolerances and high accuracy to meet specific OEM requirements."}}, {"@type": "Question", "name": "What makes OEM sheet metal fabrication cost-effective?", "acceptedAnswer": {"@type": "Answer", "text": "By outsourcing to a specialized OEM sheet metal fabrication company, you can benefit from economies of scale and expertise."}}, {"@type": "Question", "name": "How can I ensure the quality of my OEM sheet metal parts?", "acceptedAnswer": {"@type": "Answer", "text": "Look for a fabricator with ISO certifications, a proven track record, and quality control processes in place."}}, {"@type": "Question", "name": "What if I need custom designs for my OEM sheet metal parts?", "acceptedAnswer": {"@type": "Answer", "text": "A reputable OEM sheet metal fabrication company can work with you to create custom designs that meet your specific needs."}}]}Turbo Kit For Kp39,Kp39 Turbo Service Kit,Benz Repair Kit,Kp39 Turbocharger Kit

Fengcheng Fire Turbocharger Manufacturing Co; Ltd. , https://www.fireturbocharger.com